Raw Material Handling

Copper concentrate is received by ship at a wharf which can accommodate concentrate ship carrying up to 35,000 tons. A jetty, 2 km in length is constructed to reach water of sufficient depth. A wharf constructed at the head of the jetty. An unloader with a clam shell bucket, coverage capacity 600 t/h, ship loader for slag, and reversible belt conveyors are installed. Unloaded concentrate is delivered to concentrate storage yard (capacity 55,000 tons) after weighing and sampling automatically on the way. Other materials like silica, lime stone and coal are normally received by truck and stored in the flux storage building. Converting furnace slag (C-slag) is also stored in the flux building. Fluxes are then transferred by a belt conveyor to the each flux bin in the smelter and a belt scale weighs the fluxes on the way to the flux bins.

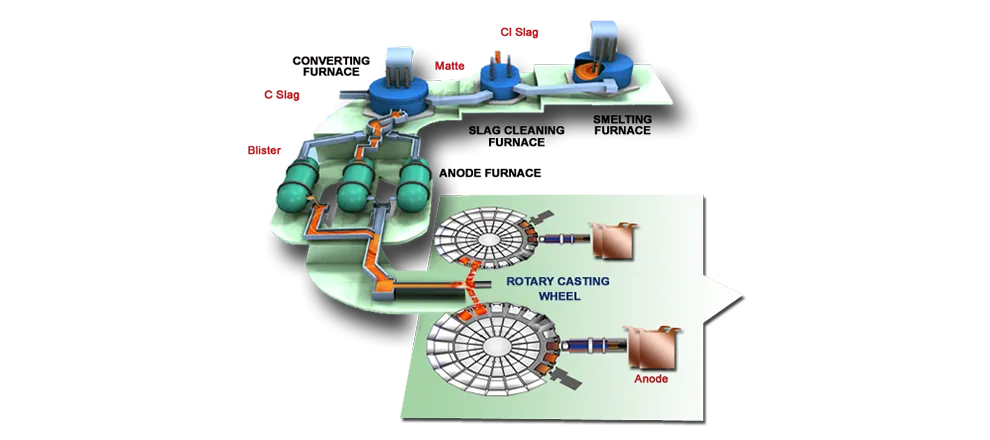

Mitsubishi Continuous Process

PT Smelting applies Mitsubishi technology for copper smelting process. The Mitsubishi process is copper continuous smelting and converting technology using three furnaces. The three furnaces are linked with covered launders, through which all the molten materials are continuously transferred by gravity.

Copper concentrate (Cu:22-29 %, S: 27-32%, Fe: 22-27%) is fed through lance pipe with oxygen enriched air into the smelting furnace then oxidized and melted by exothermic reaction to form molten mixture of matte (Cu: 68%) and slag. The matte is separated from slag by difference of specific gravity in the slag cleaning furnace. The matte is further oxidized to form blister copper (Cu: 98.5%) in the converting furnace.

The Advantage of Mitsubishi Process

High Copper (Cu) Recovery Rate

Low copper content in the discard slag (0.7% Cu).

Less Fugitive Gas Emission

Molten melt transfer through covered launder minimizes source of harmful environmental gas emission and reduces environment expenditures.

Stable & Higher SO2 in Off-gas make efficient Acid plant operation

A compact and simple design acid plant can be applied to convert SO2 in the furnace off-gases to marketable sulphuric acid.

High Efficient and Flexible Operation

High intensity reaction below the furnace lances accelerates feed material melting and has a flexibility in treating wide range and grade of concentrates and secondary materials.

Compact Facilities

Reduction of construction cost through simplified facilities.

Process Description

Utilizing advanced smelting techniques, the process involves subjecting the concentrates to intense heat, separating the copper from impurities, and refining it to meet stringent quality standards.