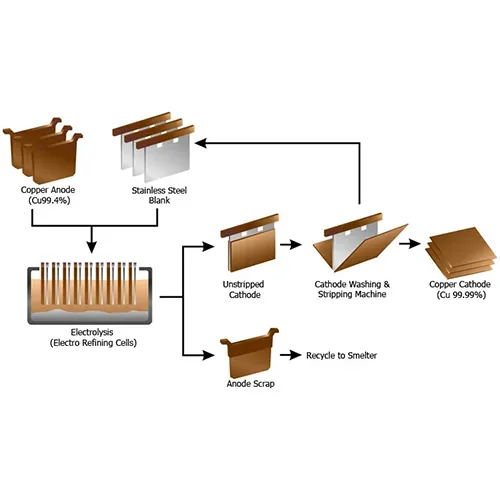

ISA Process

Copper is electro refined from anode by means of electrolysis process using SS-blank as cathodes.

Copper anodes and SS blanks are inserted in electro refining cells. By applying direct current to this cell, copper in anode is dissolved and deposited onto the SS-blank surface. Cu % in cathode is more than 99.99%. By products at Refinery are anode slime and copper telluride.

Process Description

PT Smelting refinery process is a sophisticated method for refining copper anode to produce high quality copper cathode