Smelter

Mitsubishi Continuous Process

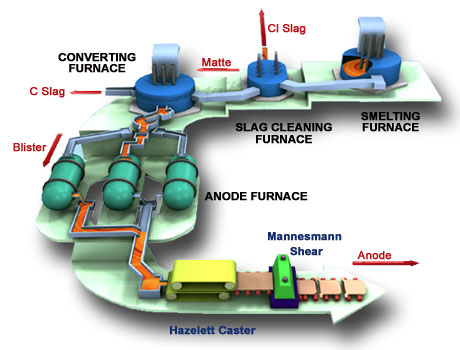

Copper concentrate (Cu:22-29 %, S: 27-32%, Fe: 22-27%) is fed through lance pipe with oxygen enriched air into the smelting furnace then oxidized and melted by exothermic reaction to form molten mixture of matte (Cu: 68%) and slag. The matte is separated from slag by difference of specific gravity in the slag cleaning furnace. The matte is further oxidized to form blister copper (Cu: 98.5%) in the converting furnace.