Welcome to PT Smelting

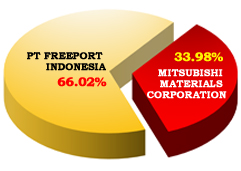

PT. Smelting is the first copper smelter and refinery in Indonesia. Establishment of PT. Smelting began when PT. Freeport Indonesia invites Mitsubishi Materials Corporation (MMC) to work together to build a copper smelter and refinery in Indonesia in 1994. Construction of PT. Smelting started from 1996 to 1998. At the beginning of its establishment, PT. Smelting plant is designed to produce 200,000 tones of copper cathode per year. PT. Smelting then carried out four times expansion in 2004, 2006, 2009, and 2023 so that production capacity increased to 342,000 tones of copper per year. On 30 June 2024, major shareholder of PT. Smelting has changed from Mitsubishi Materials Corporation to PT. Freeport Indonesia.

PT. Smelting use Mitsubishi technology in Copper smelting process and ISA technology in copper refining process. Mitsubishi process is a continuous process of smelting and converting, with a friendly environment and economically because it is able to produce anode copper with high purity, low emissions, and higher concentration of SO2 in the flue gas. ISA technology is able to produce cathode copper with a purity of 99.99% (LME Grade A) with a high operating time, high labor productivity, and high levels of safety and low production costs.

PT. Smelting has a vision to become the copper smelter and refinery plant which has a reputation and the world's most reliable and environmentally friendly. PT. Smelting has obtained ISO 9001 and ISO 14001. Additionally PT. Smelting also implemented 5S program to always maintain optimum productivity and implementing Kaizen for continual improvement. Various awards have been achieved by PT. Smelting, such as: PROPER Green, Green Industry Award, 2nd Place in the national energy efficiency awards.

PT. Smelting also actively involved in empowering the community through the Community Development in the field of health, education, and environment physical development, conservation of biological diversity, entrepreneurship, and religion.